|

created

2008/03/16 last update 2010/01/28

==> NEW

Kalman

Filter with indoor GPS

|

some links:

- old

Convict beacon projects

- Höhrmann's

project (German)

- Höhrmann's

slides (German)

- Positioning

with Independent Ultrasonic Beacons

- The

Cricket Indoor Location System

- Optimal

estimation of position and heading for mobile robots usingultrasonic beacons

and dead-reckoning

Kleeman, L. Robotics and Automation, 1992. Proceedings., 1992 IEEE

International Conference on Volume , Issue , 12-14 May 1992 Page(s),2582-2585,vol.3

-

A

Simple Ultrasonic GPS System for Indoor Mobile Robot System

using Kalman Filtering,

SICE-ICASE, 2006. International Joint Conference, Oct.

2006, 2915-2918

|

|

2008/03/16

It was time to bring one of our most ambitious projects to the NXT level. We

remind the main idea, which is to have a GPS-like system composed of several

beacons that send out infrared signals together with ultrasonic bursts. The

infrared flash of a single beacon almost arrives instantaneously at the robot

that is equipped with a combined infrared/ultrasonic receiver. But the ultrasonic signal

only arrives with a

certain delay, due to the "slow" sound velocity, in comparison to the speed

of light. The receiver is able to measure the time lag between both signals and

deduce the distance between the robot and the beacon.

The main issues with the previous

devices were:

|

|

- accuracy was

limited to about 4cm

- multi-robot

applications weren't possible

- neither the

IR-sender nor the ultrasonic transmitter were optimal in terms of power

efficiency, with the result that the system was too much directionally

sensitive and thus could not be used in larger rooms

- synchronization

between the beacons was too difficult and needed several RCXs

GENERAL DESCRIPTION OF THE NEW SYSTEM:

- indoor robot

navigation

- allows multi-robot

localization

- error less than

1cm

- low current

dissipation

- tested over a

range of 10 meters

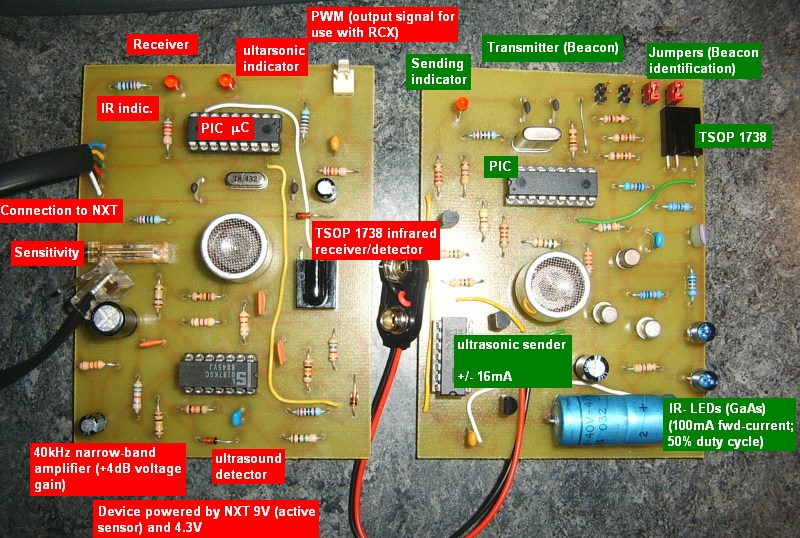

1. BEACONS

- participation of

up to 7 beacons that may be placed at strategically interesting places

- the beacons send out strong IR and ultrasonic signals that don't require

reflectors on the receiver side

- like RF-beacons,

these beacons transmit their identification number, making localization easy

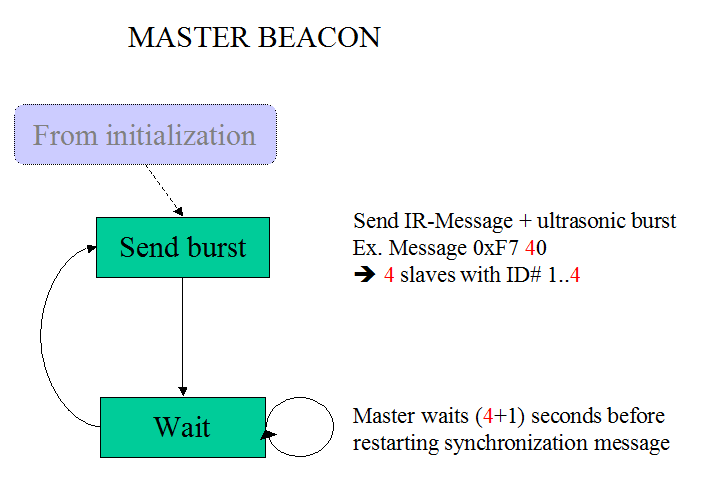

- always one beacon

acts as the master beacon, sending out a synchronization message to all

other slave beacons

- the master beacon

with system ID=0 transmits out a standard RCX compatible IR 0xF7 message. The

lower nibble of the message-value is Master_ID#

= 0. The higher nibble is the number of participating slaves N_s.

(Example: If there are 4 slaves, the message-value will be 0x40.) Note

that the beacon doesn't expect any reply on 0xF7 messages, as it also is

the case with the RCX.

- After successful transmission of the IR-message, the master-beacon sends out a short ultrasonic

burst of 1.25ms duration at 40kHz. Now the master waits

(N_s+1) seconds before

restarting the procedure.

- Then the system

waits exactly 1 second, after which the first slave sends out its 0xF7

IR-message. The message-value now is Slave_ID#

= 1. After correct IR-transmission, the slave produces a short

ultrasonic burst.

- The beacons are

jumper configurable. (One jumper defines whether the device acts as the

master, the other three jumpers set the Slave_ID# or

in the case of the master the number of participating slaves N_s.)

- Each beacon is equipped with an infrared receiver (obsolete in the case of the master). If

the slaves receive a master-message (with low nibble 0 and high nibble

<>0), the slave calculates its wait-time before being able to resend the

signals. (Slave1 must wait 1 second, Slave2 waits 2 seconds and so on.).

This procedure guarantees that the master beacon synchronizes the whole

system. (The pause between sending, now being 1 second, could be reduced in a future

firmware with a lowest limit of 35ms needed for sending the 0xF7 message

composed of 9 bytes plus the ultrasonic burst.)

2. RECEIVERS

- Any participating

robot must be equipped with a receiver. There is no limit for the number

of receivers, because the receiver-devices do not interact.

- The receiver is

NXT-compatible. It is powered from the NXT and is configured as aa I2C-slave,

answering to NXT requests.

- If a receiver gets

an infrared identification number message from on of the beacons, a

timer is started. It is stopped, once the ultrasonic burst has been received

too, or if a timeout occurred (after about 56ms). The minimum detectable

delay is 0.87 microseconds, which is due to the oscillator clock 18.432MHz

and the timer pre-scale of 1:4, one cycle being 4 clock pulses. This delay

corresponds to a path-length of the ultrasonic signal of x=c*t

=343*0.87E-6=0.3mm, assuming that the sound velocity at ambient

temperature is 343m/s. The firmware uses a 16bit timer that under the given

configuration produces an overflow after 56.88ms, corresponding to a distance of 20m.

- The receiver

stores a long message at each measurement event (data-struct

see below), composed at this point of the development of non-changeable system

information and beacon data.

- I2C requests from

the NXT force the device to return the beacon-data to the NXT-module.

Device address is 0x40. The device sends multi-bytes, among which a valid-data-state

value, indicating, whether the current data is (or is not) being changed

by a new measurement. Further the current device-time of the measurement

and the distance in cm (two bytes big endian). The beacon-data packet is

completed by a checksum.

In

the actual firmware only the beacon data is available In

the actual firmware only the beacon data is available

|

|

3. NXTs

- the NXT equipped

robots should know the positions of the various beacons

- for slow motion

robots the current position can be deduced by trilateralization

- fast moving robots

need additional dead-reckoning methods fed into a Kalman filter in order

to find a best estimate of the position.

- NXTs must provide

the 4.3V AND the 9V power-supply for the receiver-device. The data is

asynchronously retrieved through I2C.

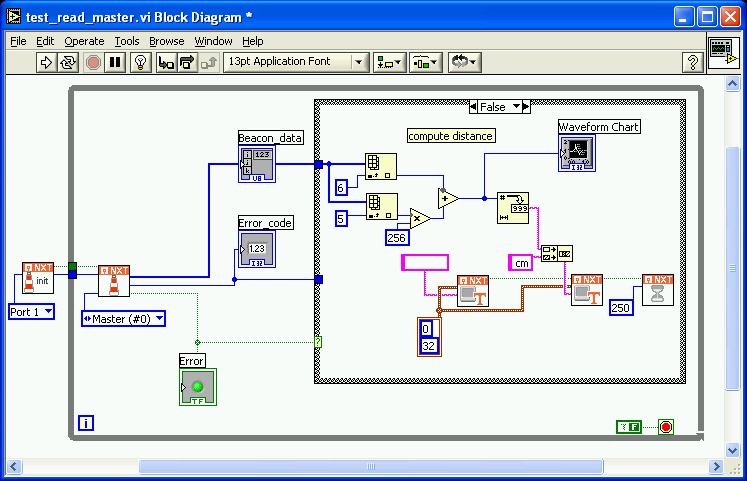

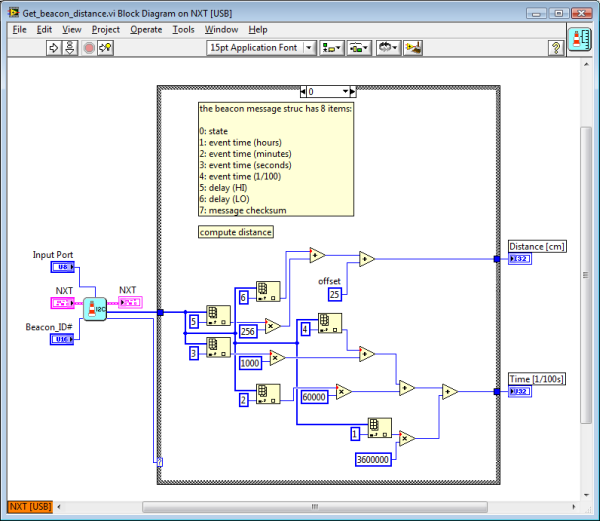

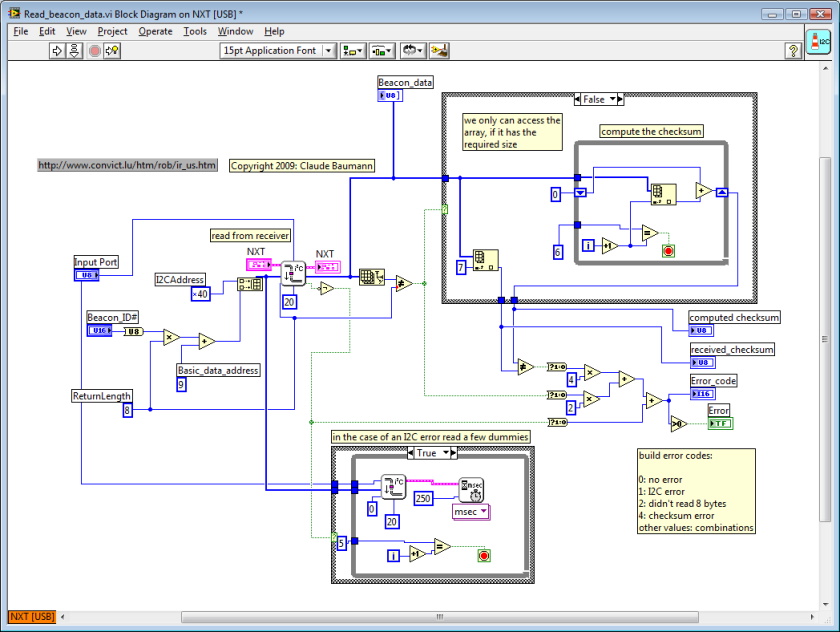

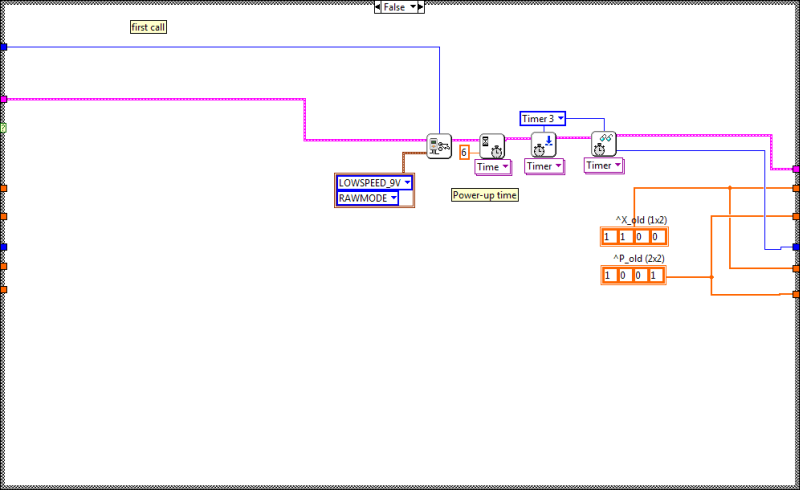

Here a simple ROBOLAB 2.9.4 program that fetches

the beacon_ID#0 data from the receiver and

displays the results:

Thanks Chris Rogers for the

hints. (I2C sub.vis may be found in ..\ROBOLAB29\vi.lib\Swan\Swan.llb)

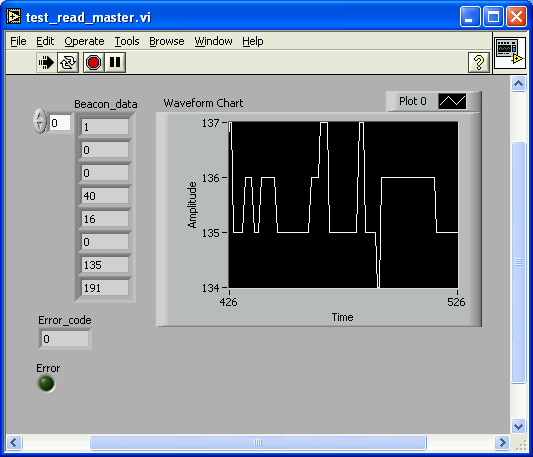

With the LabVIEW toolkit, we get the

following results:

Note that, at this

point of the development, the time stamp only indicates the time since the start

of the receiver.

4. Test-results:

The first tests with the device show the

following results:

Notes :

-

For test

reasons, the 16bit timer value that determines the measured distance in

maximal 65535 steps of 0.3mm is converted into cm, with an obvious loss of

information.

-

These first

tests do not distinguish constant errors that are due to the constant offset

of the ultrasonic detector, from spurious errors.

-

Future firmware

will return the raw 16bit timer value that the NXT can convert into distance

through x=c*t.In order to get even more precision, the user could add a

temperature sensor that might help fixing the thermo-variable sound

velocity.

5. Schematics

Characteristics:

-

beacon jumpers : XXX Y,

where XXX = ID# number (or, in the case of the master beacon number of

slaves N_s); Y = Master (set); Slave (cleared)

-

beacon IR-sender: transistors

T1/T2 work as a digital AND-function. If the TX line goes LOW, T2 is

conducting and the carrier signal

switches T3 via T1 powering the IR-LEDs. The circuit assures 100mA fwd current

through the LEDs, producing a very high infrared light intensity. The

carrier-signal is generated through the PIC16F628 PWM module.

-

beacon ultrasonic sender: the

2x3 IC3 4069N drivers allow sufficiently strong currents through the ultrasonic

transducer that oscillate between -16mA

and +16mA , thus generating a high

ultrasonic signal strength. The oscillation at 40kHz is generated through

alternating HIGH/LOW states of PIC16F628 RA1/RA2.

-

The receiver ultrasonic

amplifier has high gain, with a significant maximum at 40kHz. The following

signal detector has reaction speed less than 40 microseconds. This delay

produces an offset that should be taken into account in the evaluation of

the distance measurement.

-

The sensitivity of the

comparator should be regulated to produce best reaction in the presence of

40kHz ultrasonic signals. Since the sensitivity voltage is proportional to

the battery voltage that directly powers the amplifier, the comparator

will react similarly at any battery level. (Regulation of the sensitivity

should be done with the volt-meter applied to the output of the

comparator.

-

Note : The receiver PWM output does

not work in the present firmware.

Last minute changes:

-

Laurent Kneip

suggests that beacon transistor T3 should be added a 200Ohm resistor

between collector of T2 and base of T3, in order to

prevent too high BE-current.

In the

realized beacon circuit, PIC16F628 pin RB3 produces the 38kHz infrared

carrier instead of RB0 (not changed on the schematics

yet.) In

the realized receiver firmware, the IR and ultrasonic red LEDs have been

exchanged inadvertedly (correct on the PCboard-photo

below) added on 2008/03/18 : when

sending IR-signals, there is a voltage drop that is sufficient to trigger

the infared receiver on the beacon circuitry. We therefore added a 100nF

capacitor directly soldered between the power-supply pins of the TSOP1738.

(neither indicated on the schematics nor visisble on the photo.) the schematics indicates

TSOP1740, which is wrong.

6. PC-boards

7. PIC

firmware

The firmware has been realized

with ULTIMATE for PICs.

|

|

2009/01/24

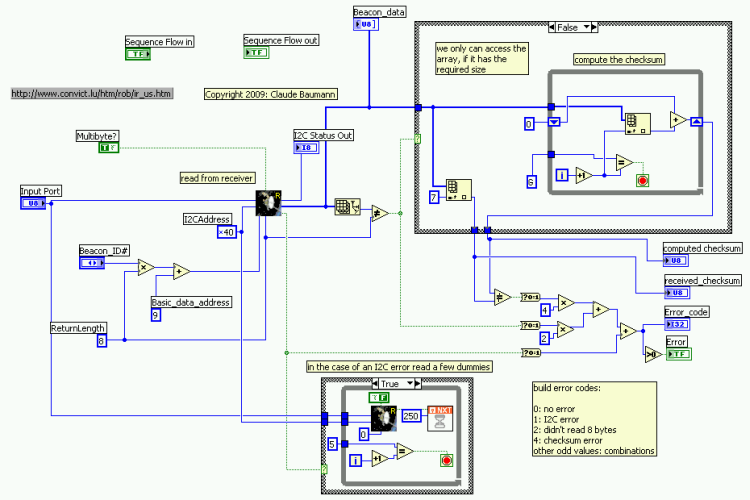

8. addons

-

We

got our copy of Michael Gasperi's book "LabVIEW for LEGO Mindstorms NXT".

Great job Mike! So, it was time to start playing with the toolkit again.

-

Since

this project was still on the workbench, it seemed to be the very first to

get the input from the book.

Updates

from the former version (cf. point 3 above):

-

Download LV7.1

NXT toolkit code

-

Much

simpler code; consequent use of the sequence wire; creation of sub.vis

-

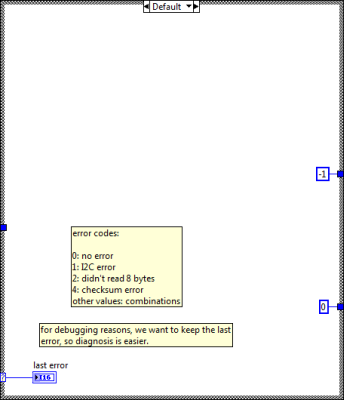

We

added error messages for the three main error states:

For

some reason the PIC firmware does not add the very first "1"

(denoted "valid") to the data-checksum computation. This probably

caused some headache to those who tried to rebuild the system. Sorry for

that. In the NXT toolkit program, the first array-field therefore isn't

counted either (which also was done above, but we forgot to mention it!!) -

There

is a nasty bug that needed a long time to be fixed: in earlier tries, if an

error occurred, the program just stopped with the mention on the NXT

display: "file error". The reason for it was that through the

program we are using dynamic data-arrays that may have zero size in the case

of an error. If then we attempt to read at any index, the NXT traps in a

fatal error state and stops the program. There is no warning or error

message in LabVIEW for this event, neither during design-time nor debugging

time. (NI guys, consider adding that error message on the PC-screen!!!) We

are pretty sure that non-experienced users will seek during extremely long

time and desperate here. Mike, could you add a note on your web-site as a

complementary instruction to your book?

|

|

2009/03/25

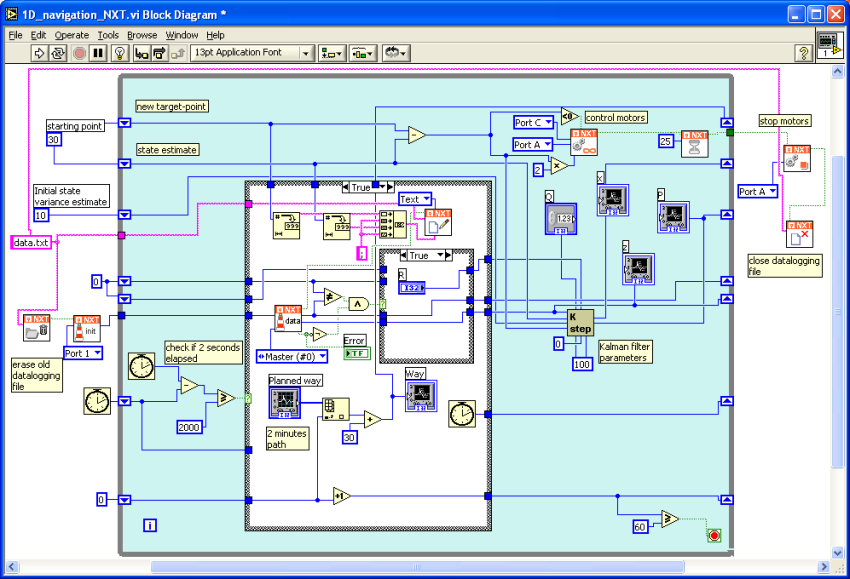

9.

1D-navigation with a scalar

Kalman filter

The

infrared-ultrasonic beacon-system represents a real global positioning system.

Navigating a robot with such a system is as difficult as using a real GPS. The

main issue that we already dealt with while developing our soccer projects

-where we used the LEGO camera as global positioning system- is that we receive

the GPS-data with a certain delay and at uncertain moments. Normal averaging

methods can retrace the robot path, but cannot control it, because they don't

tell us the actual position. Here now for the very first time, we are using a

scalar Kalman filter for driving a robot on a straight line, where we want the

robot to follow a 1D-trajectory. This means that the robot should meet certain

target-points at precise moments.

The

beacon system uses the Master-beacon alone with the receiver. But we configure

the Master so that it thinks there was another Slave beacon. By this way, we

only send a new update every second. By comparing the received time stamps and

verifying GPS-errors (let's denote the system as such), the NXT deduces whether

there is a valid update. The data is fed into a scalar Kalman filter that we

wrote entirely in the LabVIEW toolkit -no matrices were necessary-. The Kalman

filter essentially predicts the robot's position from the sensor data and its

internal model of the motion-system. It then compares the prediction with the

new sensor-values and adjust the statistics of the positioning-processes and

readings. Finally the prediction is corrected to form the very best estimate of

the robot's position along the straight line.

The

motors are controlled from the differences that are noticed between the

different target-points and the estimated positions.

The

program logs the data into a text file from which we extract the results. DOWNLOAD

PROGRAM.

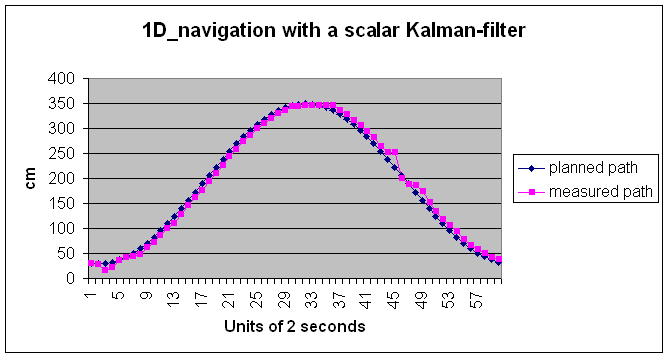

-

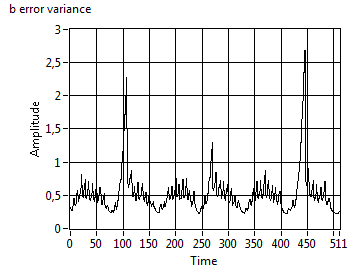

Notes:

-

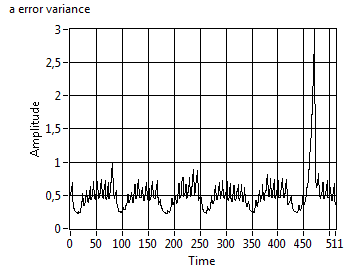

As usual for any Kalman

filter, the very first values may diverge from the real values, but

they rapidly converge, as can be seen on the picture.

-

In this particular case,

since the filter must obey a planned path, the measured path must follow

with a short delay

-

Depending on the filter

parameters, the Kalman filter has a more or less rapid response to

changes or even errors in the measurement. An error occurred at unit 45

causing the filter to react strongly by increasing the robot's speed.

|

|

2009/04/18

10. The PIC

firmware details

As

explained above, the system combines a set of beacons with a NXT compatible

receiver. The devices are driven by PIC 16F628 and 16F88 respectively. We have

been asked, if we could publish the source code. As it is written in Ultimate

for PICs, it represents a graphical code that may be easily understood as a kind

of flow-chart programs.

Links:

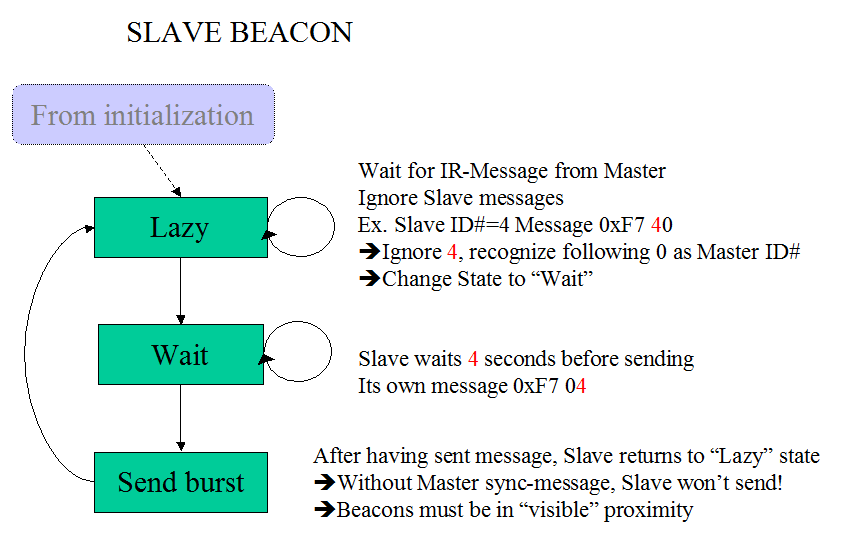

For

better comprehension we add the beacons' state machines hereby.

-

Note

that the infrared receiving for the beacons and the receiver works in

interrupt mode. This means that as soon as a new serial byte is received,

the ISR (interrupt service routine) immediately checks, whether the byte is

valid, e.a. that it corresponds to the expected byte. Since the IR channel

uses the very robust standard LEGO RCX protocol, each message has a fixed

header 0x 55 FF 00, followed by the fixed message code and its complement 0x

F7 08. Only then follows the message byte and its complement and the packet

checksum plus complement. If at any time the expected byte is missing, the

infrared RX channel is reset.

-

The

infrared channel is configured 2400 odd 1. Note that the RX channel does not

verify the parity, although the 9th bit is configured. (The parity bit only

has been added to complete the LEGO RCX message, if ever it was desired to

verify the message sending by the beacons easily without other additional

hardware than the standard RCX. (Interesting link about the RCX serial

configuration: http://www.robotika.sk/mains.php?page=/projects/rcxbt/

)

-

The

beacons also need the serial TX channel, which is used in back-to-back mode.

After the first filling of the TX-output buffer, the TX interrupt is

activated. At each interrupt, the buffer is refilled with the next byte,

until all have passed. When the first byte is send, the 38kHz infrared

carrier is activated (in PWM mode). The carrier only is stopped -and the

serial TX interrupt, after two dummy bytes have been filled in the TX,

because the otherwise the last two bytes in the PIC hardware buffer would

not be covered by the carrier signal. This causes a delay of 2x9x417us=7.5ms

(2 bytes, 9 bits, 1/2400 duration per bit) before the ultrasonic burst is

sent.

-

==>

Therefore the receiver will be not be able to measure distances to any

beacon below 7.5E-3*343=25.5cm !!! (speed of sound c=343m/sec)

-

The

receiver I2C channel is configured in "Slave" mode. The NXT should

provide the Master pulse. Since we learned that the bit-banged NXT I2C

master sometimes gets lost in waiting for a certain ACK that might never

come, we decided to verify every 1/100th second, if the state of the I2C

channel is hooked somewhere. If it is longer than 5 seconds in the same

state, the whole communication modules (also the UART) are reconfigured.

This important measure helped reducing the errors to almost zero, even with

multi-byte messages.

-

Some

minor features still are not implemented.

|

|

2009/10/22

11. Localizing a NXT robot in 2D with the iGPS

This

took quite a long time for the journal to awake. But, here we are again.

NEW:

-

We

finally builded a second beacon, etched the PC-board, soldered the parts,

plugged the battery... and without any trouble it immediately worked.

-

The

beacon wait-time has been reduced to 250ms instead of 1sec.

-

==>

Now we will be able to navigate in the plane with our robot

-

We

rename the whole system iGPS (= indoor Global Positioning System)

-

Recall

that two beacons are sufficient to navigate in a determined half-plane

(the beacon line must then be one of the main axis.)

-

iGPS

allows multirobot application, because receivers don't intervene in

sending infrared or ultrasonic bursts

-

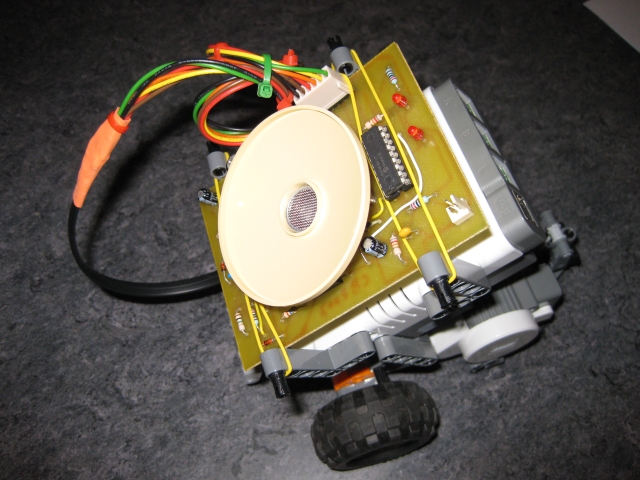

If

the beacons are placed almost in the same plane than the receiver, we

recommend adding a reflector to the ultrasonic receiver. (Unfortunately

the IR-receiver is shadowed, but this doesn't matter, because the

IR-pulses are so striong. We used the LEGO part that LDraw denotes

"Dish 8x8 Inverted" (see next picture) and drilled a hole in

the middle.

-

The

NXT now is programmed with LabVIEW Education Edition (LVEE)

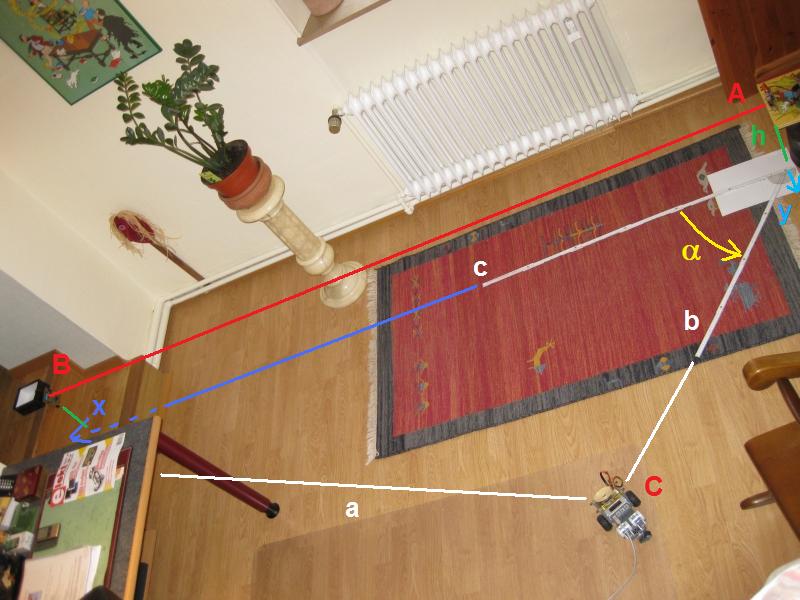

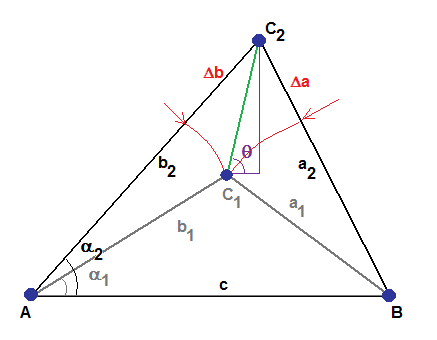

We are able to localize the robot in

the plane by applying the cosinus theorem. Note that in the very first test, we

deliberately ignore that the beacons height.

We manually measure 54°.

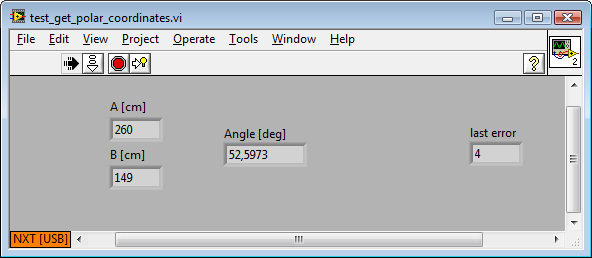

And the NXT yields the robot polar

coordinates C(52.6°, 149cm):

Here all the LVEE codes:

|

|

2009/10/23

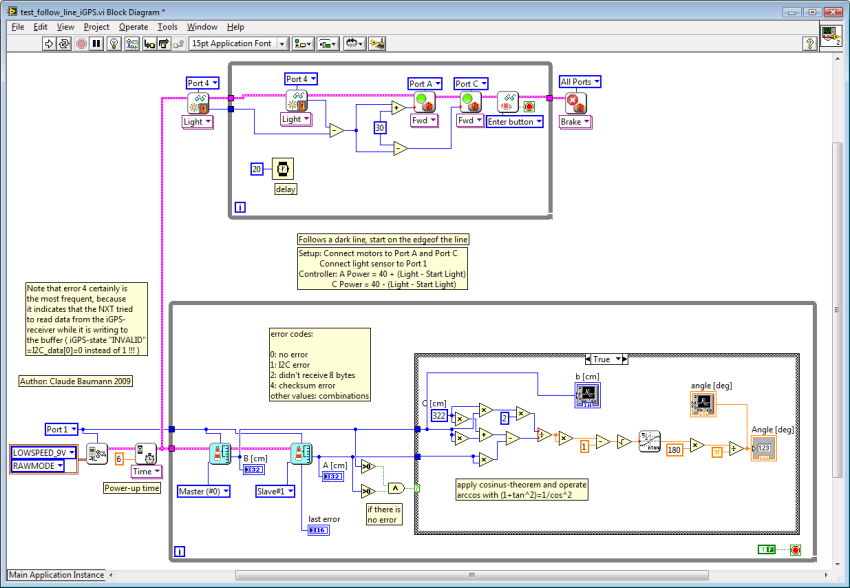

11. Follow

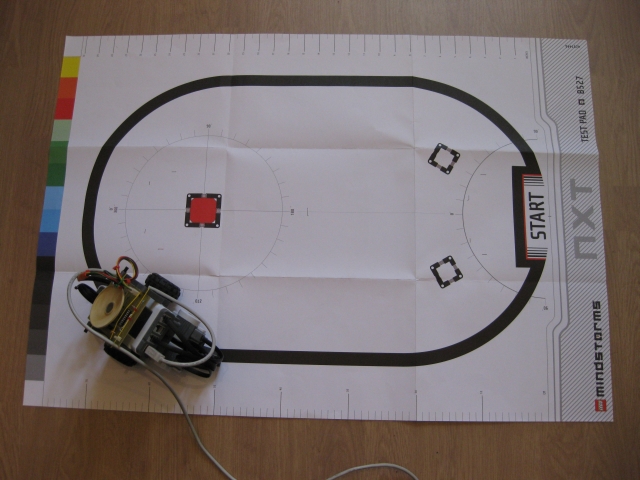

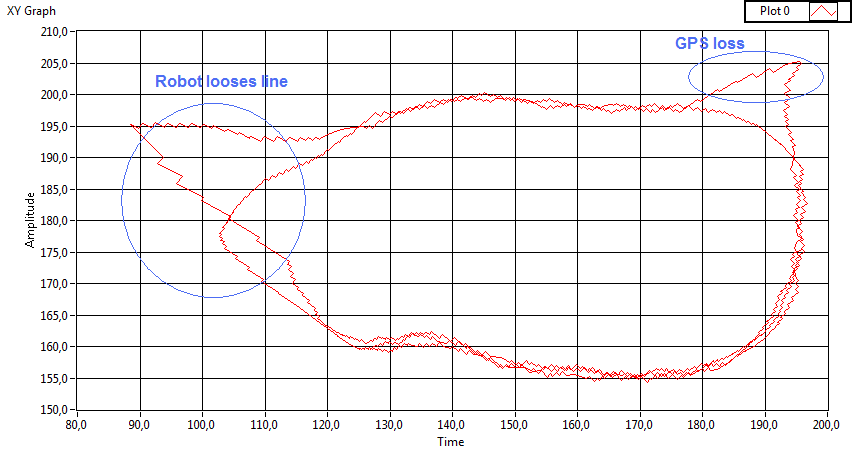

a black line and localize the robot with the iGPS

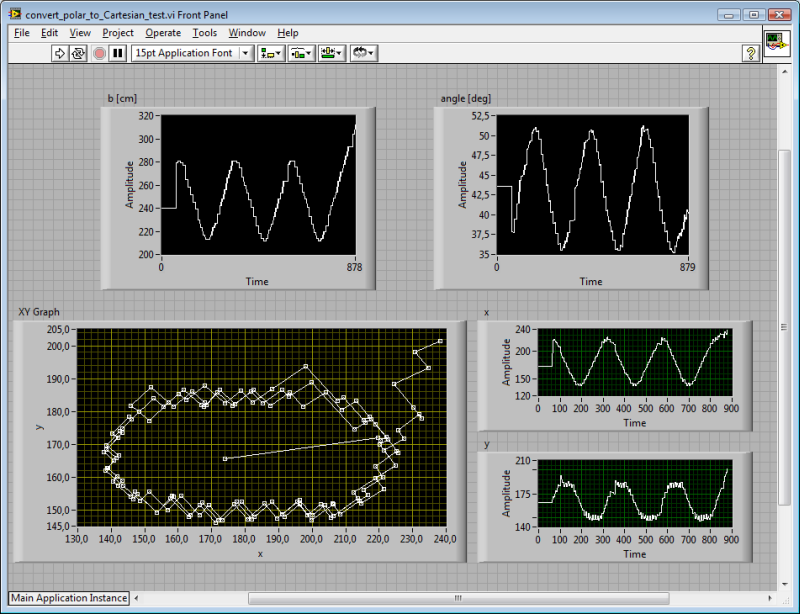

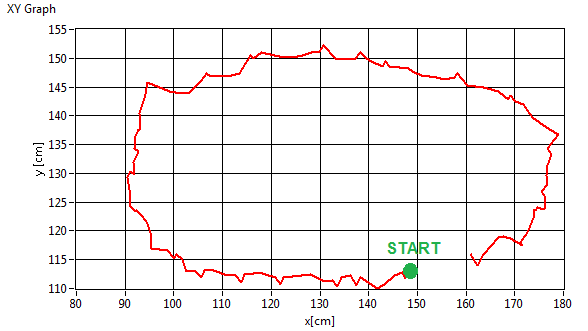

In order to test the reliability of

the 2D-localization with the iGPS, we programmed the robot to follow a black

line and upload the localization data to the PC. The program was run in

debugging mode with the USB-connection. Then we "manually" dragged and

dropped the data into a new VI, converted the polar coordinates to Cartesian

coordinates and plotted the computed positions.

Notes:

-

Inadvertently we exchanged the

master and the slave beacon, so the resulting graph is mirrored

-

The program uses the LVEE

line-follow behaviour

-

The constant c=322cm was not

measured, but just estimated. Its inaccuracy and the fact that we still

ignore the height of the beacon locations explain the distortion of the

curve.

-

The robot uses the light sensor

in order to detect the black line. The algorithm does not produce the usual

bang-bang line following, but a very smooth reaction.

-

The last turn, the robot lost the

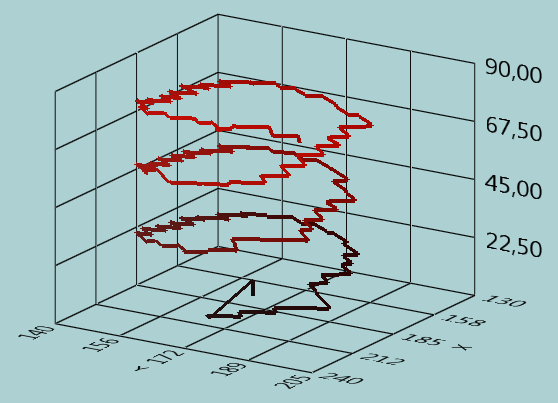

line and went off the oval.

-

We draw a 3D-graph in order to

show how the three turns that the robot takes overlay.

-

The zig-zag in the line come

from the fact that the actual position is only deduced from iGPS data that

is off phase by 250ms.

|

|

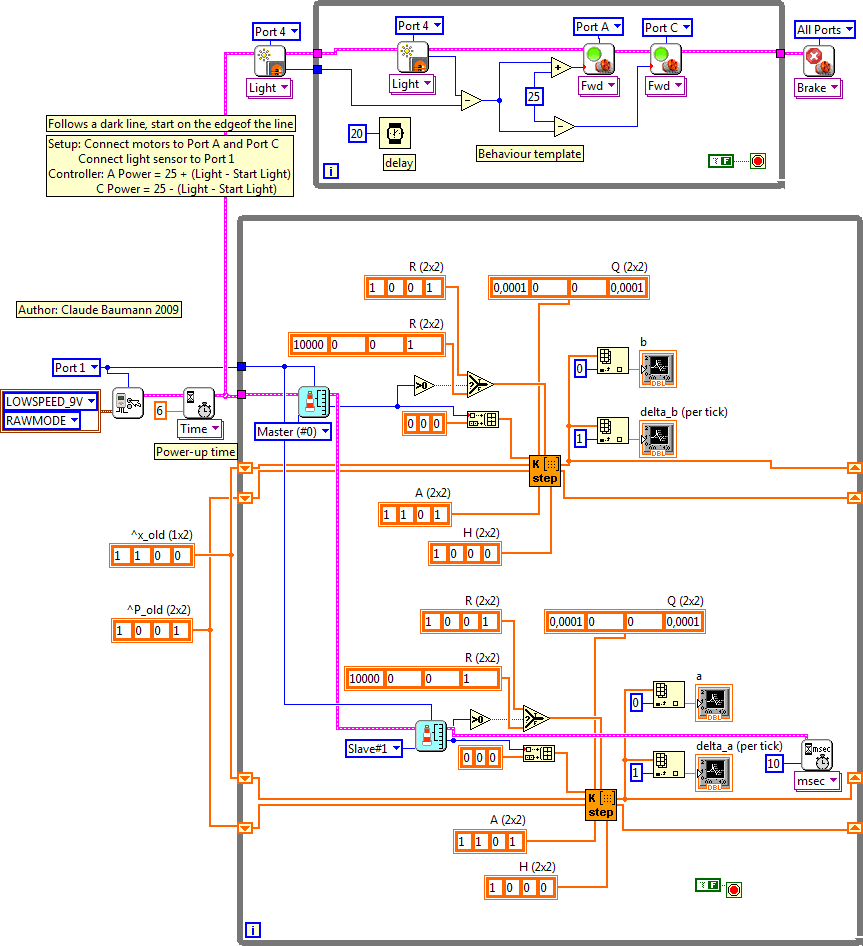

2009/10/27

12. Follow

a black line, localize the robot with the iGPS, while processing the data with a 1st

order Kalman filter

By now we have presented the scalar Kalman

filter on this site. But, in order to efficiently navigate a robot with our iGPS

system, we must this time implement a first order Kalman filter. This implies

that we need to build a matrix-based filter that is able to describe the process

as a state-space model with a state variable that is composed of a process

variable and its derivate.

There are not many people who have played with

the Kalman filter on LEGO bricks. Here a list of the most important available

online work:

As usual we wanted to write the Kalman filter

code in LabVIEW Educational Edition. There is one important limit to the

implementation: the LabVIEW toolkit does not support 2D arrays. The solution to

this issue is to reshape the 2D matrices into 1D-vectors and pick all the data

from there. That's exactly, what we did. There are some important limitations:

- The Kalman filter step function is limited to first order state space models and thus uses 2x2 matrices.

- Since the LV NXT-compiler does not support 2D arrays, all 2x2

matrices are reshaped to 1x4 vectors, where the order is: a11, a12, a21, a22

(The first index indicates the row, the second one indicates the column)

- The state variable is a 1x2 vector, because a first order state space model has only depth 2. (However, due to a compiler

bug, the vector must be filled with zeros to 1x4.)

- The measurement vector is 1x1 or 1x2. (Fill up with zeros to 1x4)

The control vector is 1x1 or 1x2. (Also fill up with zeros to 1x4)

- R must be 2x2.

Now let's try to model the robot. First, we

consider the black line as the planned path. We don't need to tell the robot

more about the path, as we did in the 1D-experiment.

Instead the line following algorithm and the black line are responsible for this

task. To keep all linearity, we localize the robot in triangular coordinates, as

explained above. Once localized, with no effort we can turn these coordinates

either in polar or Cartesian coordinates. Because the triangular coordinates

represent distances to beacons, let's denote the main variable

r

that represents the radius of

the circle with center beacon M

. (Practically, in our case, r

either equals a or b and

M

is beacon A or B.) We have the equation:

which expresses the fact that the next position

is defined from the old one and its derivate (the speed). As a discrete time system, we

assume that  and we prefer the index k to the time index t:

and we prefer the index k to the time index t:

We define the state as:

Recall the rules of matrix calculation. (A review

is really indicated, before continuing)

This equation suggests that the derivate does not

change over time, which in reality is not true. Yet for the moment we will

ignore that the process suffers from disturbances and is not submitted to

control.

For now we only rely on one single measurement

z(k)

hat is related to the state variable through the equation:

and where

v(k) is the measurement noise. Note that the product of

a horizontal vector with a vertical vector is a scalar and the noise

v(k) has the same dimension.

Thus,

z(k)

is a scalar (with matrix dimension 0). Notice that, when defining the parameters

for a Kalman filter, it is always essential to follow the dimensions of the

various matrices. The following schematics of the Kalman filter procedure has

been copied so often on the web -without reference- that we reproduce it here

with all the credits to the authors ( http://www.cs.unc.edu/~welch/media/pdf/kalman_intro.pdf

). Note that it was picked from THE Kalman filter reference site: http://www.cs.unc.edu/~welch/kalman/index.html

:

Q describes the process covariance.

In the present example, the robot movement is part of the process noise, because

in the equation above, we didn't add any control variable. In fact, B

and u(k) are always zero in our example. Q and P

have the dimension 2x2. We assume that the noise of the position and the speed

are not correlated (which is obviously wrong, because any disturbance in the

speed also changes the position and vice-versa.). Therefore the non-diagonal

matrix elements are set to zero. Why such an assumption then? Q is one of the

most important parameters of the Kalman filter. As Q gets smaller

compared to the measurement variance R, the Kalman filter believes

more the model than the measurement. Anyway, during the process, the error

covariance, which is a fusion of the process covariance and the measurement

variance, will show that the errors in position and in speed are correlated.

The dimension of the Kalman factor K

must be 1x2, because in the Update equation (2) it multiplies with the

scalar

z(k) .

Remember that a few lines ago we underlined that

z(k)

had dimension 0. We also have seen that the product H.x(k) is a

scalar.

also represents a scalar that you may easily verify

through the following example:

also represents a scalar that you may easily verify

through the following example:

Hence, R must be a scalar. However,

the current LabVIEW sub.vi does not verify the dimensions of the matrices. On

the contrary, it is programmed to always operate the 2x2 inverse matrix.

Therefore it is essential to design R as a 2x2 diagonal matrix

with a dummy 1 in the right corner. Otherwise, the inverse matrix function will

return an error value.

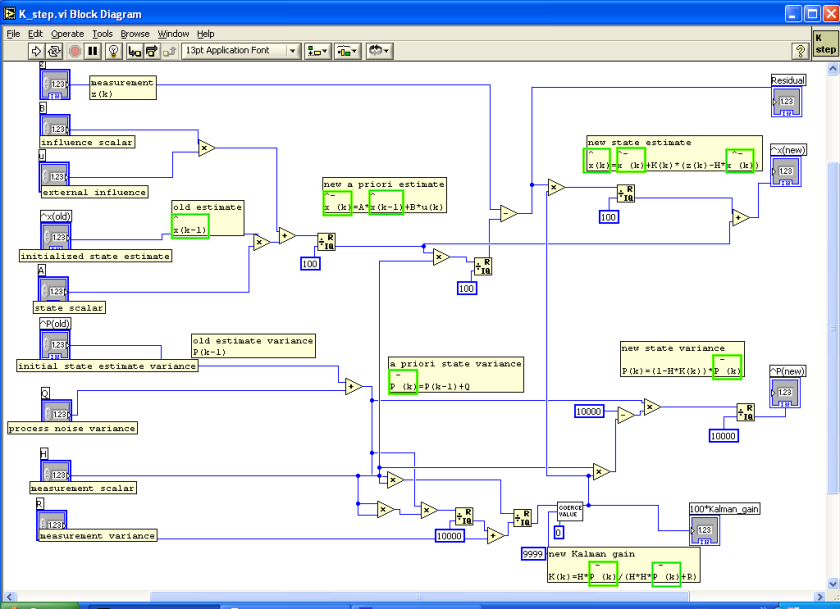

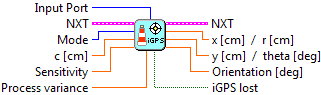

Here the first order Kalman filter step function.

It looks impressively complex, but its execution only takes 15ms on the LEGO

NXT, which must be considered as excellent timing.

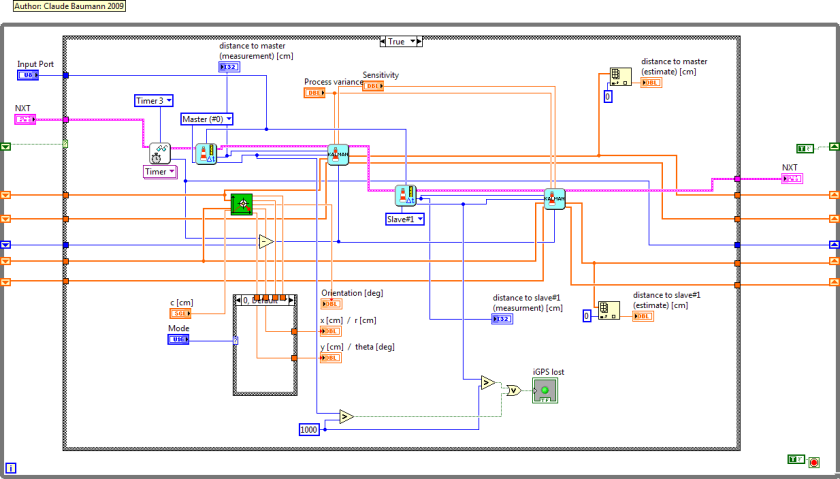

And the iGPS navigation program changes to the

following diagram. Notice that we increase the variance R, if the

iGPS data is invalid. The high variance tells the filter to ignore the last

measurement. The reaction of the filter is very impressive. We could improve it,

if we dynamically increased the sensor variance, as the duration from the last

valid measurement increases.

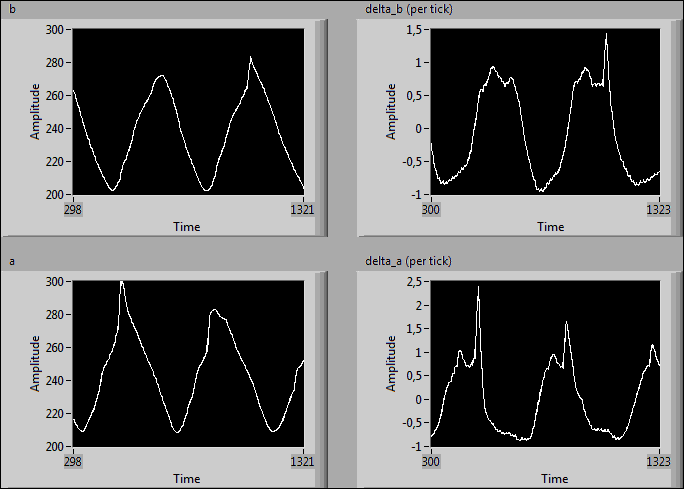

It is astonishing that the two events, on one

hand the robot loosing the line, on the other loosing the iGPS signal, do

generate the same kind of error in localization. The difference in reality was

that during absence of the iGPS signal, the robot continued moving correctly on

the line, whereas the second time, the robot completely went off the line and

had to be replaced manually. Without any other knowledge, from the data alone,

we cannot distinguish both cases. But, the loss of the iGPS signal can be

compensated, if we add a second sensor to the system. We try to improve the data by

dynamically adapting the measurement variance in function of the elapsed time

since the last correct reading of a beacon value.

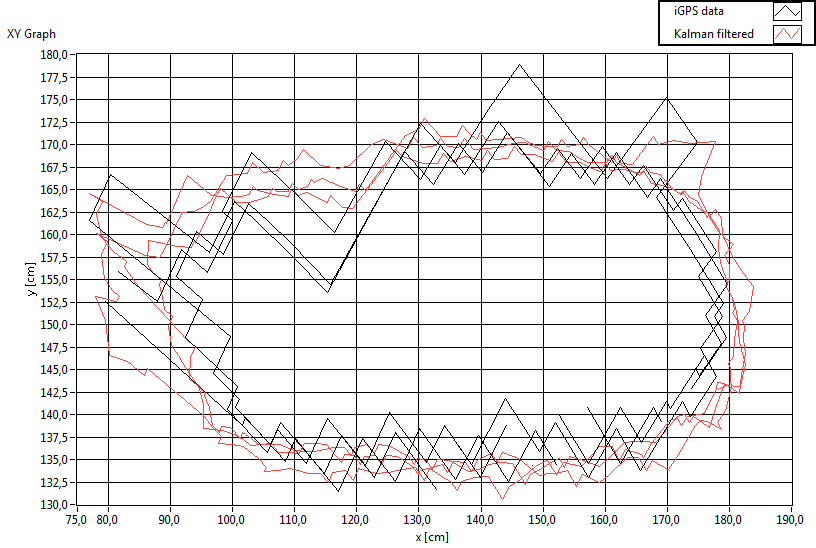

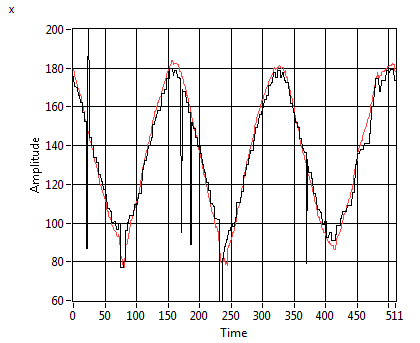

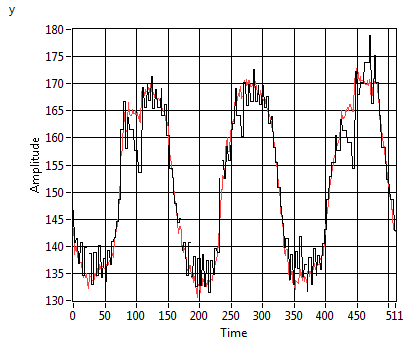

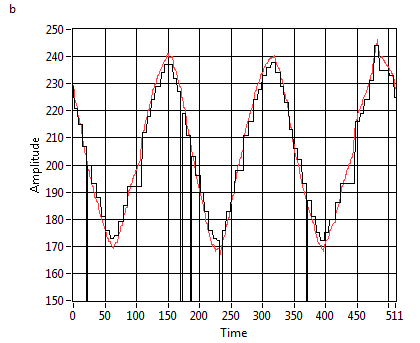

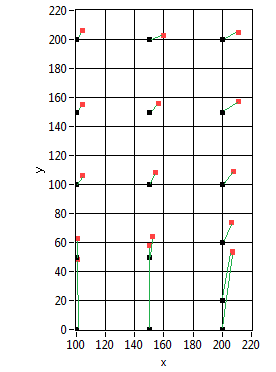

The following xy-plot is the result of a very

small process variance Q=0.0001. Remember that this value,

compared to R=1 indicates that the Kalman filter should believe

more -but not explusively- the model prediction than the sensor reading.

|

|

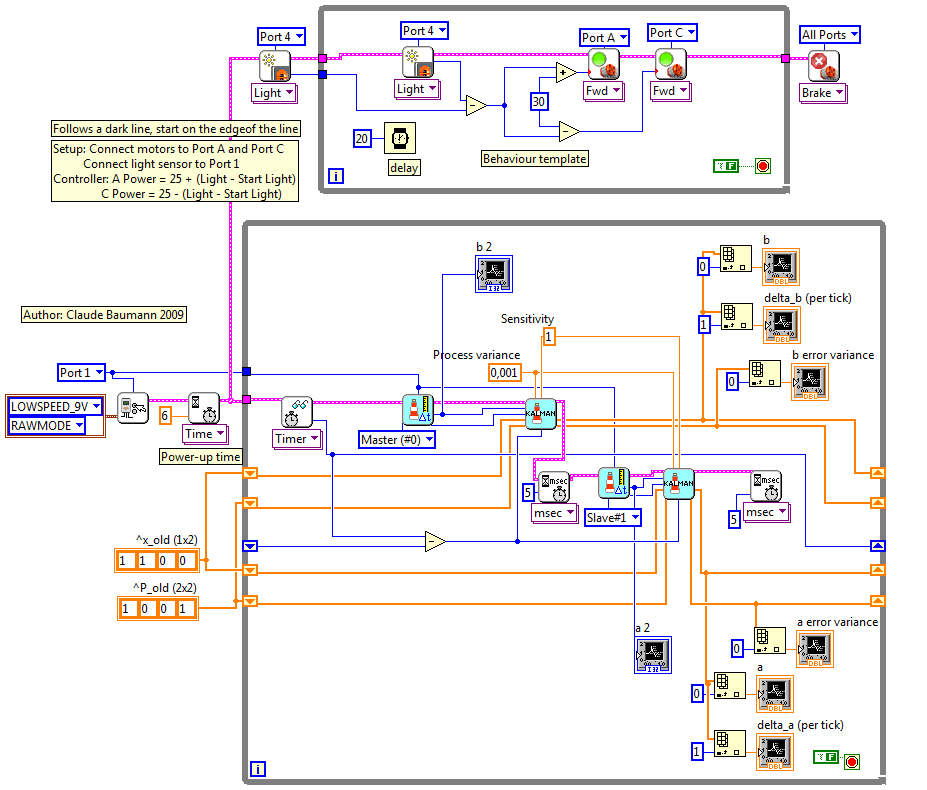

2009/10/28

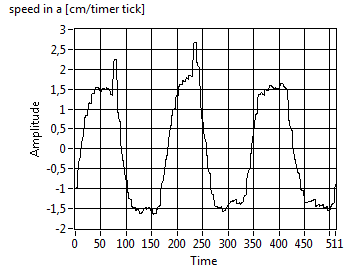

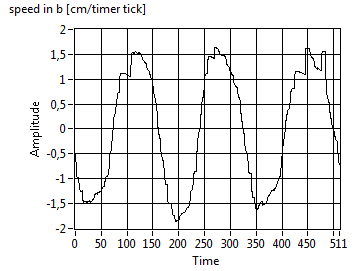

We now use another iGPS sub.vi that returns the

distance to the beacon and, for each beacon, the elapsed time in milliseconds

since the last valid data. Obviously, if we have a valid measurement at a

certain moment, we will have to wait 500ms, until the beacon sends again. During

that time, the robot will displace by about 3cm and the sensor value that enters

the Kalman filter has worse variance. Therefore, the iGPS Kalman filter function

computes the travelled distance since the last beacon update and increases the

measurement variance R accordingly. Now, the filter error variance

is no longer fixed to the convergence value, but changes over time.

In the next example, the resulting graph is less

smooth, because we tolerated a higher process variance. Note the additional

variable "Sensitivity", that is a scale factor for the influence of the elapsed time since the

last valid data.

Tuning the filter is not too complicated. As a

rule of thumb, we should compare (overlay) the measurement and the estimation,

and adjust Process Variance and Sensitivity in order

to get a smooth curve. We added a scale factor "h" to

the iGPS_Kalman filter VI that helps squeezing the resulting curves. (Note that,

if the filter is too strong, it looses actuality (phase-shifting) and also

stretches the curves. So, for post data processing, a stronger filter might be

preferred, but in a life application, actuality is more important.)

|

|

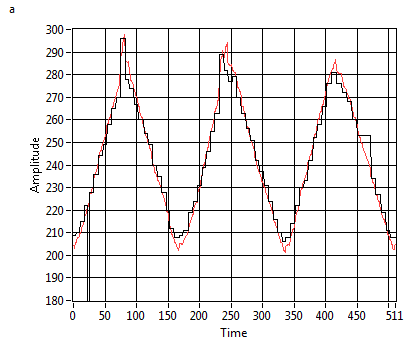

2008/10/29

The information that the iGPS system has gathered

with the Kalman filter is sufficient to also yield the orientation of the robot.

The main idea is to use the latest estimation of the beacon distances and the displacements in the

triangular coordinate system and convert them to cartesian coordinates, while

deducing the orientation. Anyway, since there is no other measurement of the

orientation that might correct the prediction, we can assume that this

estimation will be the best that we can do. Thus, this ahead fixing of the robot

orientation will depend on the overall error of the filtered data. However,

because the transformation into Cartesian coordinates is no longer linear, the

error will not propagate in a linear way either. The easiest way to estimate the

errors that propagate through the non-linear system is applying the Gaussian

method. Here a few references that introduce this method:

If the variance of the orientation is needed, the

program should include the calculation of two discrete derivates and apply the

error propagation formula for variances.

Another idea is to operate a Taylor linearization

of the non-linear functions and tranform the Kalman filter into an Extended

Kalman Filter (EKF). (This is not indicated here, since the actual matrix Kalman

filter is only implemented for 2x2 matrices.)

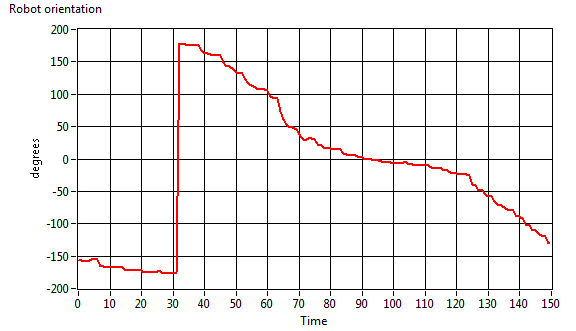

Another test gives us the orientation during a

robot run over the circuit:

|

|

2009/10/30

13. Convert the

triangular coordinates into Cartesian coordinates

Now the program should convert the triangular

coordinates from the iGPS trilateration into Cartesian or polar coordinates. As

we already pointed out, this conversion-functions are no longer linear. For our

present project however, this does not matter, because with the excellent

precision of the iGPS distance data, error variances can be assumed very small.

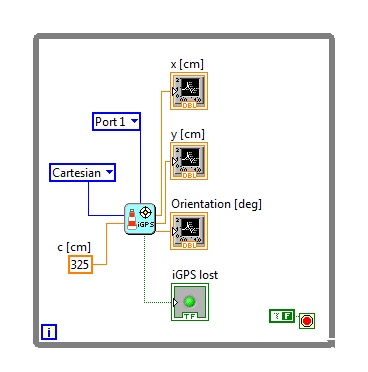

But, we will test this. The LabVIEW program that is run in debugging mode

appears very smart:

For it was possible to run the device with

approximate beacon positions. Also we corrected the offset by a constant (25cm

that we tried to explain above - probably we were wrong in the interpretion).

- We noticed that weak beacon 9V block-batteries

have an effect on the offset, although the receiver is stable for beacon

battery voltages down to 8,3V. Below this value, the offset grows.

- There are no differences between the master

and the slave beacon. (A study here can only be made, once we have more

beacons.)

- The NXT voltage does not affect the readings.

- We took off the plastic reflector, because we

found that the shadow on the IR-receiver was too bad and also increased the

offset.

- The offset is slightly dependent on the

distance. So, we add a correction function to the main distance extractor

VI. (d=1.0191*x+4.2133).

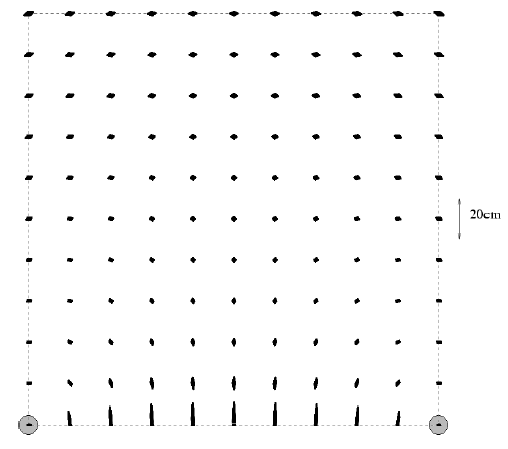

The very first tests yields the following graph

- Note that the results are based on the Kalman

filter data and that the filter has not been fine tuned yet. from the graphs

above, you can see that the filter slightly overestimates the true values

- The standard deviation never exceeds 1 [cm]

both in x and y.

- The graph is very similar to the thoroughful

study of the Höhrmann's

project, from which we pick the error-graph of a simulation with a

two-beacon scenario.

- Beacon spacing was 325cm

- Errors are largest between the beacons

Conclusions: The results can be improved, if the

Kalman filter is tuned. This however may take quite a long time.

|

|

2009/10/30

14. Some more tests

- long range test without reflector:

- beacon and receiver aligned: maximal

measurable distance 16.40m

- beacon at 2m height, receiver horizontal:

maximal distance 5.70m ==> might be an idea to rethink about using a

reflector; but the plastic reflector above hides the IR-receiver!!!

- The team will build 2 more beacons. So, there

will be 4 and complete 3D-positioning will be possible.

|