Gyroscope project : Journal

- March 2001

- Decision to buy the piezoelectric gyro from IKARUS.

This gyro must be addressed using R/C servo communication.

- 26/3/01 - 30/03/01

- Building a pulse generator for R/C servos following

the circuit from Gordon McCOMB, The Robot Builder's Bonanza,

USA, 2001, ISBN 0-07-136296-7, p. 305ff.

- Building Ralph Hempel's R/C Servo

Interface for the RCX

- Installing legOS

for advanced programming (tests with 0 ... 255 motorpower-levels instead

of traditionnal 0 ... 7)

- First tests of the gyro using the servo pulse

generator and a R/C servo--> gyro works perfectly

- First tests of the servo interface to the RCX. The

problem of working with R/C servos is that they must be addressed with a

1 - 2 ms positive pulse. The pause between the pulses is irrelevant for

the information, it must however stay between about 14 - 25 ms.

Ralph Hempel's interface and the RCX platform allow

only two states:

- motor power is set to 6: this causes the RCX to

send a positive pulse of 7 msec and a 0-pulse for 1 msec. The interface

inverts the signal.

- motor power 5: 6 msec HIGH-state; 2 msec LOW-state

The programmer has to observe the turning speed of the

servo, or -as overkill- to add angle-reading for exact adjusting.

- Tests with legOS and the following program showed

that the minimum pulse is 1 msec, even if the incrementing is less than 1

msec:

/* servo.c*/

#include <unistd.h>

#include <dmotor.h>

#include <conio.h>

int main(int argc,char **argv)

{

int k;

/*start the motor at power 0*/

motor_a_speed(0);

motor_a_dir(fwd);

msleep(1000);

cls();

lcd_int(0);

/*speed up gradually and display value*/

for(k=0;k<=MAX_SPEED;k++)

{

/*speed the motor up a notch*/

motor_a_speed(k);

lcd_int(k);

/*wait a second to observe*/

msleep(1000);

}

motor_a_dir(off);

cls();

return(0);

}

|

Conclusions: there is no possibility to send a pulse

between 1 and 2 msec using the RCX with legOS or the standard firmware. We'll have to design an own interface.

10/4/2001

Andreas Peter has designed a Two

RC Servo Motors Interface to the RCX. He has some very usefull ideas!

Perhaps he could give us the schematics and the PIC-program? We'll ask him.

13/4/2001

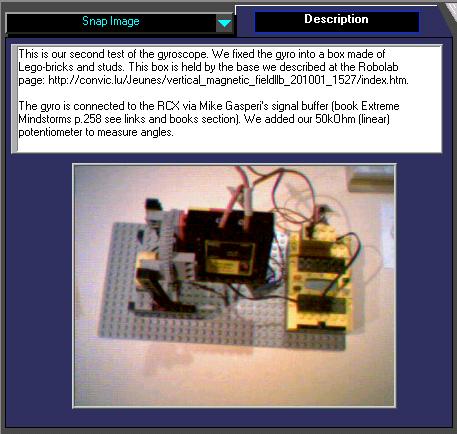

We contacted the manufacturer of the IKARUS Gyro, but the

details we got about the sensor are nevertheless scarce. After a short analyses, it

becomes obvious, that the brain of the gyro is a PIC 16C711. This PIC has a

build-in A/C converter. The conditioned information from the TOKIN ceramic

sensor must enter the PIC somewhere. We found that it is actually Pin 11 of the

PIC. So we tried to buffer the signal first to our lab-instruments, then to the

RCX via Mike

Gasperi's RCX-input-buffer. (The 30mA current from an RCX-input is

not sufficient to drive the gyro. So an external battery is needed). Don't use

an RCX-motor output!! Because of ground-problems.

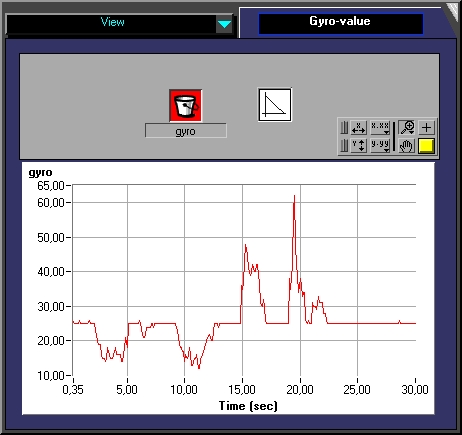

The gyro was mounted on the RCX (It is possible to stick

it between two Lego-bricks!) Gyro-sensibility manually to 100%. We chose our direction-master (I) for the tests.

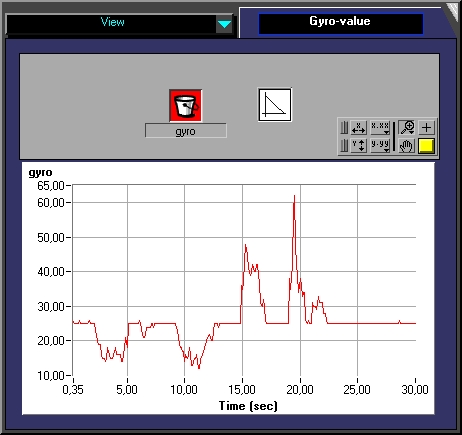

We programmed some heading changes and stored the data in the memory through

datalogging. We captured the values towards the PC. The heading is

expressed in degrees, dH/dt is the derivative of the heading through

time. The gyro values are raw values from 0..1023. To fit them in the graphics,

we used the formula y=800-gyro_raw.

--> The gyro gives the derivate of the

heading. Some mathematical transformation has to be done. First the zero-point

has to be detected, then probably a proportional adjusting.

17/4/2001

If the gyro is used as designed by the manufacturer, there

is NO need to build an own servo-interface, since Ralph Hempel's interface may

be used on his PBForth platform. PBForth has two keywords SERVO_INIT and

SERVO_KEY to generate any pulse width from 0.50 to 2.50 ms. It's even possible

to drive two servos from one output (by setting the mode-option and replaceing

the Graetz-diode-bridge by an unilateral circuit. (book: 'Extreme Mindstorms'

p.313)

20/5/2001

After a longer pause we work again on this project.

We operated some additional tests using the following

device. The rotation sensor is connected to RCX input 2 :

RESULTS: SEE

THE ROBOLAB-FILES

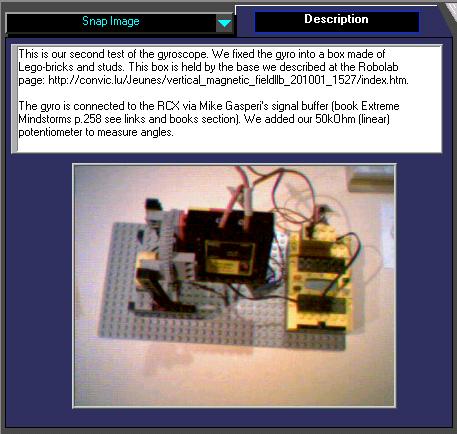

30/10/01

We are working now with Robolab

2.5 ! This marvelous program has some very interesting features such

as the possibility to integrate textual program-parts. Many things are improved

from the previous version, but there remain some bugs, specially in the

graphical part of the compute-area. Nevertheless, we are delighted with all

these new possibilities. This software makes robot-programming reachable for

secundary students !

Main

Page

Main

Page